- Your Trusted IT Consulting Team

- info@consultant.com

- Mon - Sat: 8.00 am - 7.00 pm

- Your Trusted IT Consulting Team

- info@consultant.com

- Mon - Sat: 8.00 am - 7.00 pm

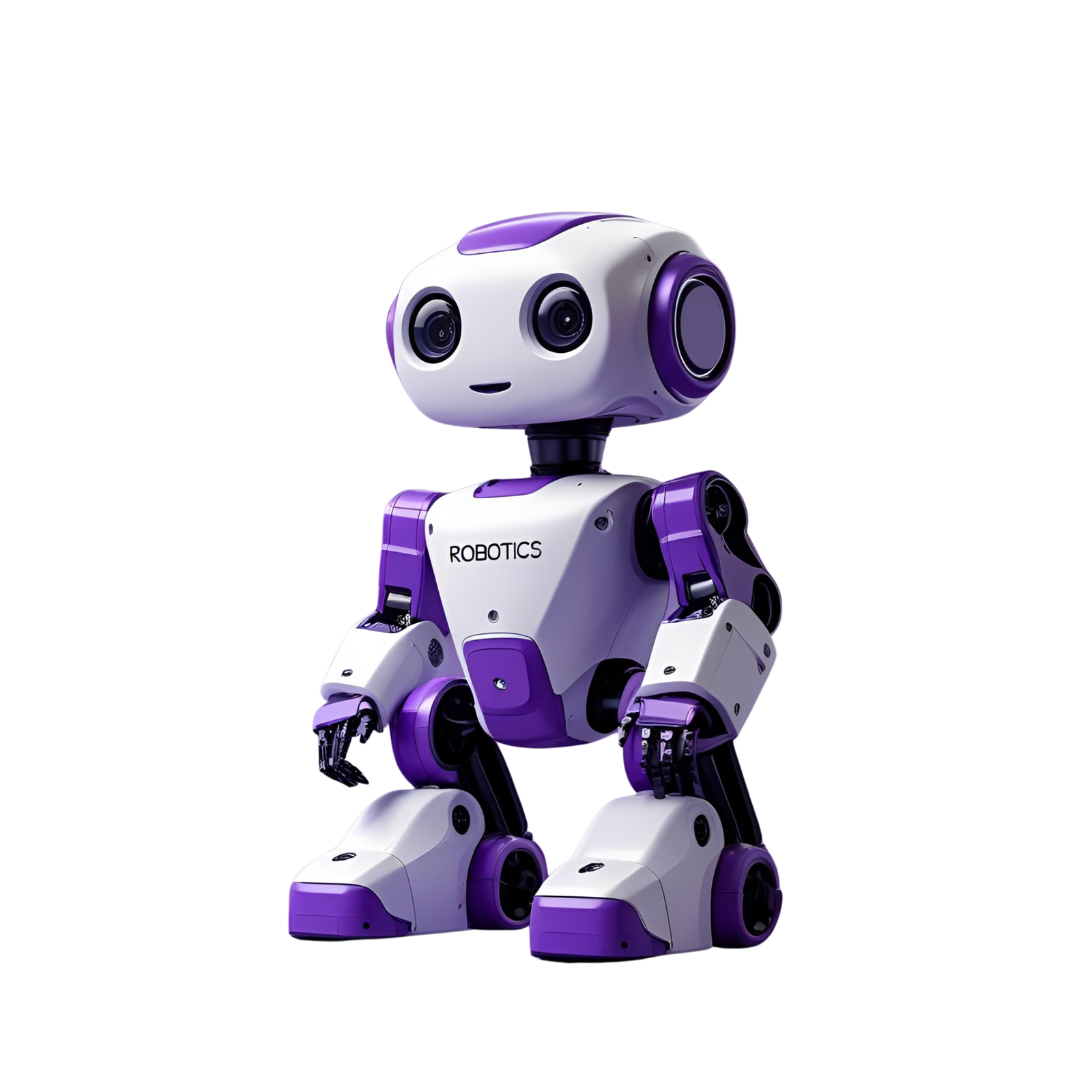

Robot Refurbishment

Reliable Robot Refurbishment Solutions

Get the reliability of a new robot at a fraction of the cost. Our refurbishment services extend the life of your industrial robots while maximizing ROI.

Sometimes replacing an older robot may be the best option, but often refurbishing it can save time and money. Most refurbishment or replacement processes can be completed over a weekend, minimizing production downtime. Our engineers provide honest consultations to help you make the best decision for your plant.

Our 14-step refurbishment process includes:

Visual inspection and physical examination to identify worn or damaged components

System backup and functionality assessment

Multi-step troubleshooting to clear errors and warnings

Pre-cleaning before physical testing

Greasing all axes and assessing stability

Complete diagnostic report and repair quote

Perform repairs, replace parts, and tune functional components

Replace grease and oil for all axes

Retest, run full diagnostics, and document results

Clean robot using dry ice and secure methods

Paint and seal robot as needed

Final testing and diagnostics

Calibrate robot to industry standards

Prepare for secure shipping, delivery, and reinstallation